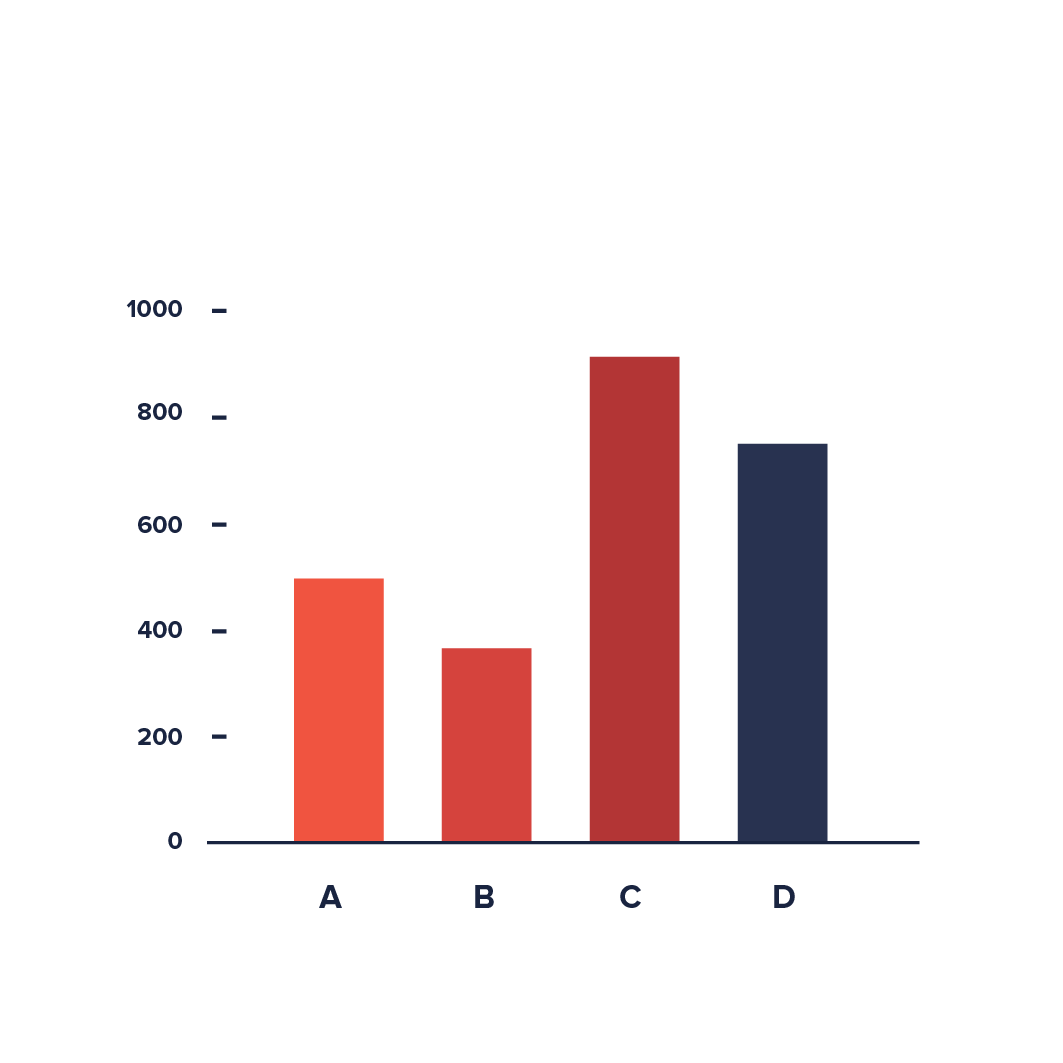

Chart minitab charts example

Table of Contents

Table of Contents

Are you struggling with monitoring and controlling your process outputs? Do you want a simple and effective way to track your performance over time? Then you need to learn about Example Of P Chart Calculation!

When it comes to production processes, there are always fluctuations in output. But without a way to measure and analyze these variations, you can’t make informed decisions about process improvement. This is where P Charts come in, as they allow you to see trends and changes in your process outputs over time.

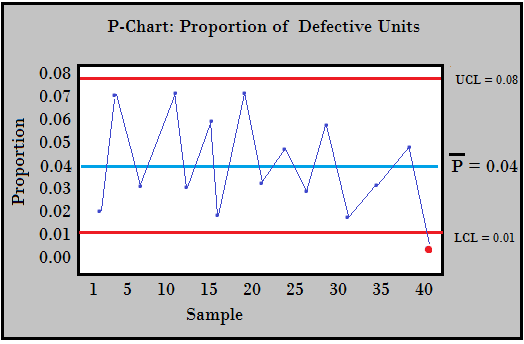

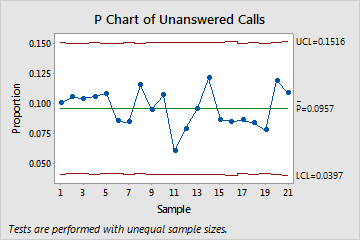

Simply put, Example Of P Chart Calculation is a statistical tool that helps track variations in process output. It plots the proportion of non-conforming units for each subgroup of a process and calculates the upper and lower control limits based on this data. By monitoring these control limits, you can quickly identify when your process is producing unacceptable outputs and take corrective action.

In summary, Example Of P Chart Calculation is a powerful tool for monitoring and controlling process outputs. By using P Charts, you can track variations over time and take informed corrective action to improve your process performance.

Target and Explanation

Example Of P Chart Calculation targets those who need to monitor and control their process outputs. Whether you work in manufacturing, healthcare, or any other field with unique process requirements, P Charts can help you track your performance over time and identify areas for improvement.

Personally, I have used P Charts in the manufacturing industry to monitor the quality of our products over time. By analyzing the data, we were able to identify a specific machine that consistently produced defective parts and take corrective action. This led to a significant improvement in our overall product quality.

How to Use P Charts

To create a P Chart, you first need to define your sample size and the proportion of non-conforming units that are acceptable. Then, take samples over time and plot the proportion of non-conforming units for each sample. Determine the upper and lower control limits based on the sample data, and monitor these limits over time to identify when your process is producing unacceptable outputs.

It’s important to note that P Charts are most effective when used in conjunction with other statistical process control tools, such as a control chart or histogram.

Benefits of P Charts

One of the main benefits of P Charts is that they are simple and easy to use. They provide a visual representation of process variations and allow you to quickly identify when your process is producing unacceptable outputs. Additionally, P Charts can help you identify the root cause of process variations and take corrective action to improve your overall process performance.

Limitations of P Charts

Like any statistical tool, P Charts do have limitations. They are most effective for processes that have binary outputs (conforming or non-conforming), and may not be as effective for processes with continuous variables. Additionally, P Charts assume that the subgroup sizes are constant and that the samples are independent, which may not always be the case.

Real World Applications of P Charts

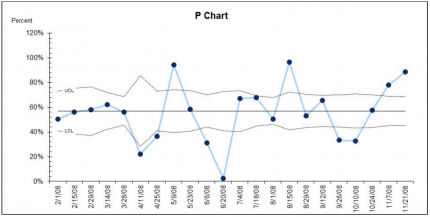

One example of the real-world application of P Charts is in healthcare, where they are used to monitor and control patient outcomes. For example, a hospital may use a P Chart to monitor the proportion of patients who develop a post-surgical infection over time. By monitoring this data, the hospital can identify when their infection rates are increasing and take steps to improve patient outcomes.

Question and Answer

Q: What is the difference between a P Chart and a control chart?

A: A P Chart is used to monitor the proportion of non-conforming units in a process, while a control chart is used to monitor continuous variables, such as temperature or pressure.

Q: How do I know what sample size to use for my P Chart?

A: The sample size for your P Chart will depend on the specifics of your process. Generally, a larger sample size will result in a more accurate representation of your process performance.

Q: Can P Charts be used for processes with continuous variables?

A: P Charts are most effective for processes with binary outputs, such as conforming or non-conforming units. For processes with continuous variables, a control chart may be a more effective tool.

Q: What should I do if my P Chart shows that my process is out of control?

A: If your P Chart indicates that your process is out of control, you should take corrective action to identify and address the root cause of the problem. This may involve adjusting your process parameters, training employees, or implementing new quality control measures.

Conclusion of Example Of P Chart Calculation

Example Of P Chart Calculation is a valuable statistical tool for monitoring and controlling process outputs. By using P Charts, you can track variations over time and take informed corrective action to improve your process performance. While there are limitations to P Charts, they are a simple and effective way to track your process performance and identify areas for improvement.

Gallery

Constructing P-Charts Lecture - YouTube

Photo Credit by: bing.com /

Is Trauma Team Performance Better, Worse Or Flat? Know For Sure With A

Photo Credit by: bing.com / chart example trauma worse sure performance flat better team know enlarge click

P-chart / P-Control Chart - Statistics How To

Photo Credit by: bing.com / chart control process statistics statisticshowto

Example Of P Chart - Minitab

Photo Credit by: bing.com / chart minitab charts example

Example P Chart : Quality Improvement – East London NHS Foundation Trust

Photo Credit by: bing.com / nhs